Compatible Options

Renegade Parts Washer Options

At Renegade Parts Washers, we offer top-of-the-line, highly customizable parts washing systems that are built to last and designed for efficiency. Whether you need a heavy-duty front-load washer for industrial cleaning or a custom conveyor system to streamline operations, our wide range of standard features and optional enhancements allows you to configure a washer that perfectly fits your business requirements.

Below, you’ll find comprehensive information on our capabilities and options, complete with images, videos, and application-specific icons to guide you toward the ideal configuration.

Reference these icons to ensure that the option you are looking at is compatible with the type of parts washer or system you need.

Material Options

- Stainless Steel Construction Upgrade

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Stainless Steel Construction Upgrade

The cabinet won’t rust.

Our washers are built with 304 stainless steel construction, 11 gauge, ensuring long-term durability and rust prevention.

This is particularly critical for industries washing sensitive parts, as no carbon steel rust can contaminate them. Stainless steel guarantees longevity and cleanliness, providing a high standard of quality. In some cases, stainless steel construction is not only a benefit but a customer requirement for handling specific materials.

Core Functions Options

- Rinse

- Dry

- Agitation Dip Tank

- Horizontal Rotating Parts Washer

- Flush Through Parts Washer

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Rinse

Rinsing provides clean, residue-free parts.

Our rinse systems ensure that any detergent, dirt, or contaminants are thoroughly removed from parts after washing.

We have three rinse options designed to meet a range of cleaning needs and budget considerations.

Rinse to Overflow

Our most cost-effective option, the rinse to overflow system uses fresh rinse water sprayed into the cabinet, which then flows into the wash water. This setup requires the overflow to be plumbed to a drain, ensuring proper disposal. The rinse pressure is comparable to the spot-free rinse at a car wash, and it can be heated for enhanced cleaning performance.

Rinse to Pump Out

For consistent fresh water with each rinse, the rinse to pump out option sprays fresh water into the cabinet and diverts it into a separate tank equipped with a sump pump. Once the tank is full, the water is pumped out. Like the overflow option, the pressure is similar to a spot-free car wash rinse, and heating is available. This system provides freshwater rinse without diluting the wash solution while being slightly less expensive than a closed-loop system.

Closed Loop Rinse

Our premium option, the closed-loop rinse system recirculates reused rinse water, directing it to a dedicated tank before pumping it back into the wash chamber during the rinse cycle. With a powerful 3 HP pump (minimum, larger washers may get a larger rinse pump as needed) delivering 45 psi at 50 gallons per minute, this system offers optimal performance while minimizing water usage. Though the initial investment is higher, the long-term water savings make it an efficient and eco-friendly solution.

Dry

Efficient drying for fast processing times.

We offer two primary drying systems:

- A heated drying cycle, pictured, operates like a convection oven, slowly and effectively drying parts.

- For faster processing, the centrifugal blower uses high-velocity air to quickly dry parts, making it ideal for high-volume production lines.

Agitation Dip Tank

Provides deep, uniform cleaning through agitation.

Our dip tanks are designed for applications that require parts to be submerged and agitated for thorough cleaning. They are ideal for industries needing intense cleaning. We can build custom dip tanks to meet specific requirements.

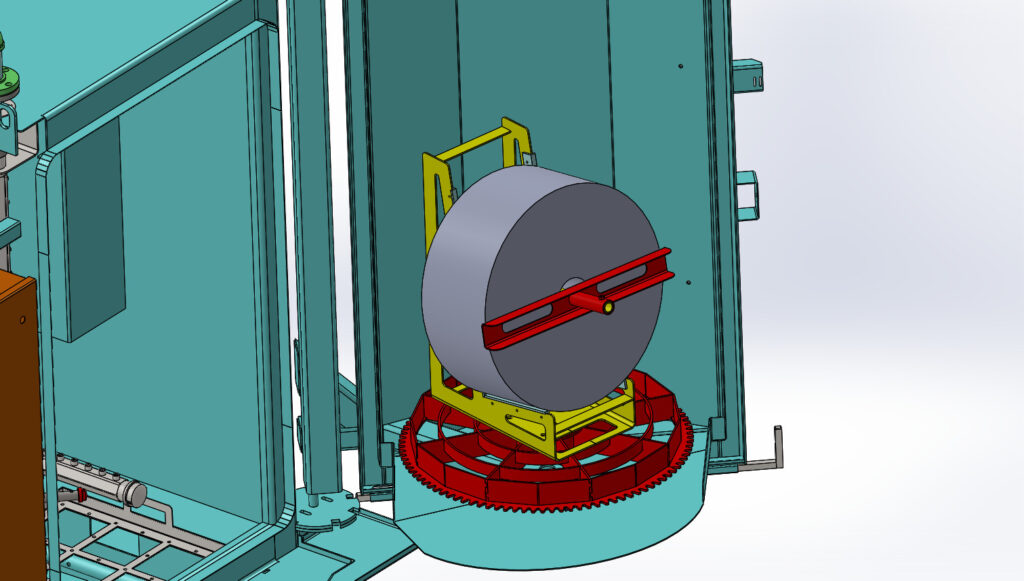

Horizontal Rotating Parts Washer (HRPW)

Rotates the part within the wash.

HRPW’s unique design features a rotisserie-style mechanism, ensuring thorough cleaning by rotating parts on their balanced centerline.

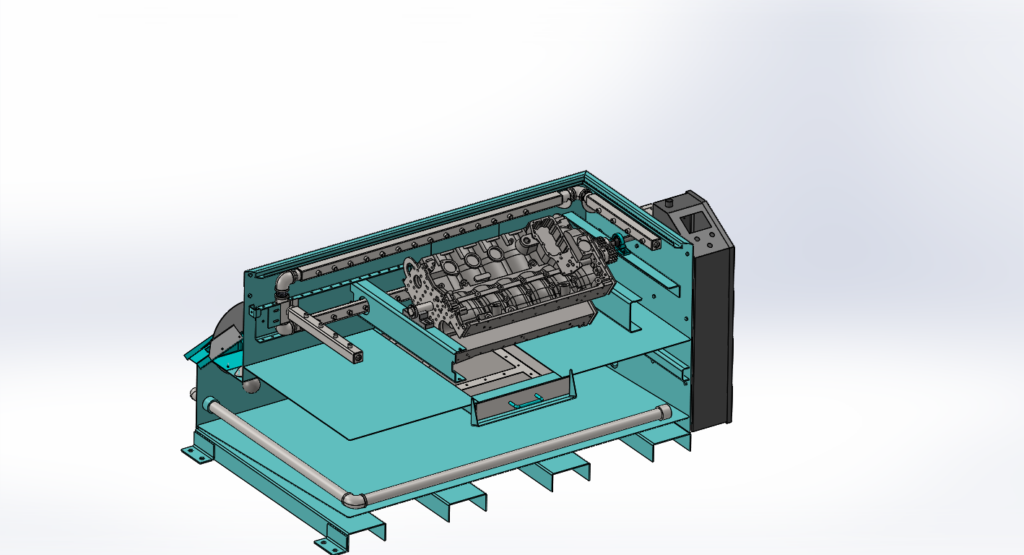

Flush Through

Washs your part from the inside out.

Our flush-through system is designed for parts with internal channels or difficult-to-reach areas. This system ensures all parts are thoroughly cleaned by flushing liquid through these tight spaces, removing any residual contaminants for a comprehensive clean.

Control Options

- Large Touch Screen HMI Control Panel

- Allen Bradley PLC

- VFD Motor Control

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Large Touch Screen HMI Control Panel

Touchscreen: Simplified control with tons of information at your fingertips.

The 12″ HMI Control Panel is our largest and most advanced interface, designed for machines with complex operations. Featuring touchscreen controls, multiple screens, and a wealth of information, this panel makes operating the washer intuitive and efficient. It’s ideal for managing multiple inputs, outputs, and sensors, offering total control over the wash process.

Allen Bradely PLC

An Allen Bradley PLC offers reliability, flexibility, and advanced control for automating industrial processes.

Designed to withstand harsh environments, these PLCs provide precise control over machinery and processes, making them ideal for industries requiring high efficiency and minimal downtime. They are highly scalable, allowing for easy expansion, and offer advanced connectivity for seamless integration with other systems. With user-friendly programming and modular design, Allen Bradley PLCs enhance automation while reducing maintenance time and costs.

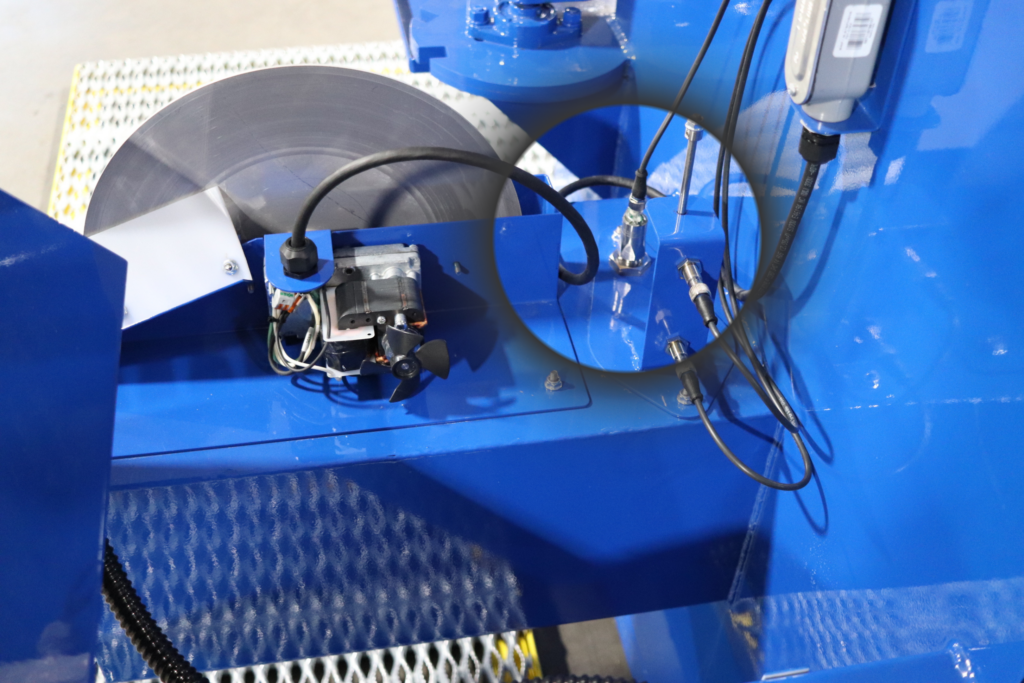

VFD Motor Controls

A VFD motor control provides precise speed regulation, energy efficiency, and enhanced motor performance in industrial applications.

By adjusting the frequency and voltage supplied to motors, VFD (Variable Frequency Drive) motor control allows for smooth acceleration, deceleration, and speed control, improving process precision and reducing energy consumption. It extends motor life by preventing unnecessary wear and tear, while offering flexibility to adapt to varying load demands. VFD systems are also easy to integrate with automation solutions, making them ideal for optimizing motor-driven operations.

Automation and Load Handling Options

- Loading and unloading interface signaling for robots or conveyors

- Overhead Jib Crane

- Pit Mount

- Crane Access Hatch

Not sure exactly what you need, call 1-800-774-7900 or contact us.

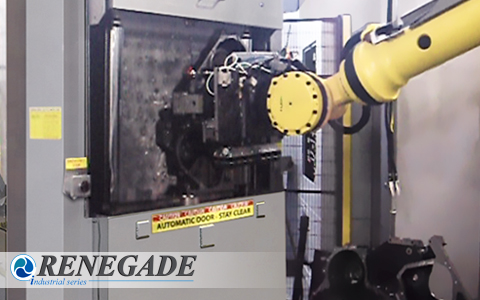

Loading and Unloading Interface

Interface with robotics or conveyors for loading and unloading parts.

We will partner with you to design and interface for loading and unloading of your parts for high-volume or sensitive applications. We engineer solutions for you.

Overhead Jib Crane

Eases the loading and unloading of heavy parts.

The overhead jib crane offers a simple solution for loading and unloading heavy parts. It provides flexibility and safety by helping operators handle larger components with ease, reducing physical strain and the risk of accidents.

Pit Mount

A pit mount parts washer offers space-saving installation, ergonomic benefits, and enhanced safety for industrial cleaning processes.

Installed at floor level, a pit mount washer frees up valuable vertical space, making it easier to integrate into tight work areas. Its ground-level design also improves ergonomics, allowing operators to load and unload parts without lifting heavy items, reducing strain and the risk of injury. Seamlessly fitting into production lines, it streamlines workflows and increases safety by minimizing the risk of dropping or spilling large parts. Additionally, pit mount washers can be customized to fit specific spaces, enhancing operational efficiency.

Crane Access Hatch

Eases the loading and unloading of heavy parts.

The access offers a simple solution for loading and unloading heavy parts. It provides flexibility and safety by helping operators handle larger components with ease, reducing physical strain and the risk of accidents.

Front Load Custom Fixture Options

- Two-Tiered Turntable

- Turn Table Containment Ring

- Parts Tree

- Turntable Top

- Custom Fixtures

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Two-Tiered Turntable

Doubles your washing space.

The two-tiered turntable is ideal for customers with smaller parts. By utilizing two tiers, you can wash twice the number of parts in one cycle, increasing efficiency without increasing the machine footprint.

Turn Table Containment Ring

Prevents parts from sliding off the table.

The turntable containment ring is a 4-inch-tall barrier that encircles the turntable, preventing parts from slipping off during the wash process. This option is especially helpful for smaller, lighter components that might otherwise be dislodged.

Parts Tree

Optimizes space by hanging parts.

The parts tree fixture allows users to hang parts vertically, maximizing the number of parts that can be cleaned in a single cycle. This method of hanging parts ensures they receive thorough cleaning from all angles.

Turntable Top

Prevents small parts from falling through.

Our turntable top fixture is designed with a laser-cut, fine mesh to prevent small parts from slipping through the gaps in the standard turntable. This option ensures even the smallest components are safely secured during the cleaning process.

Custom Fixtures

Engineered to your parts and loading needs.

Top Load Custom Fixture Options

- Shallow Basket

- Small Parts Basket

- Rotary Part Fixture System

- Part Tumbling Baskets

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Shallow Basket

Moves smaller parts closer to the center for improved cleaning spray.

The shallow basket is ideal for smaller parts, positioning them better within the spray arms for a more thorough cleaning. By elevating smaller components within the wash basket, this fixture ensures efficient cleaning without the risk of parts being lost in the machine.

Small Parts Basket

Keeps small items secure.

The small parts basket is specifically designed for tiny components like nuts and bolts, preventing them from getting lost during the wash process. This basket ensures even the smallest parts are thoroughly cleaned and accounted for.

Rotary Parts Fixture System

Rotates parts for an even clean.

The rotary part fixture system allows parts to be rotated during the wash process, ensuring every surface is cleaned evenly. This fixture is especially useful for intricate or uniquely shaped components that need complete coverage.

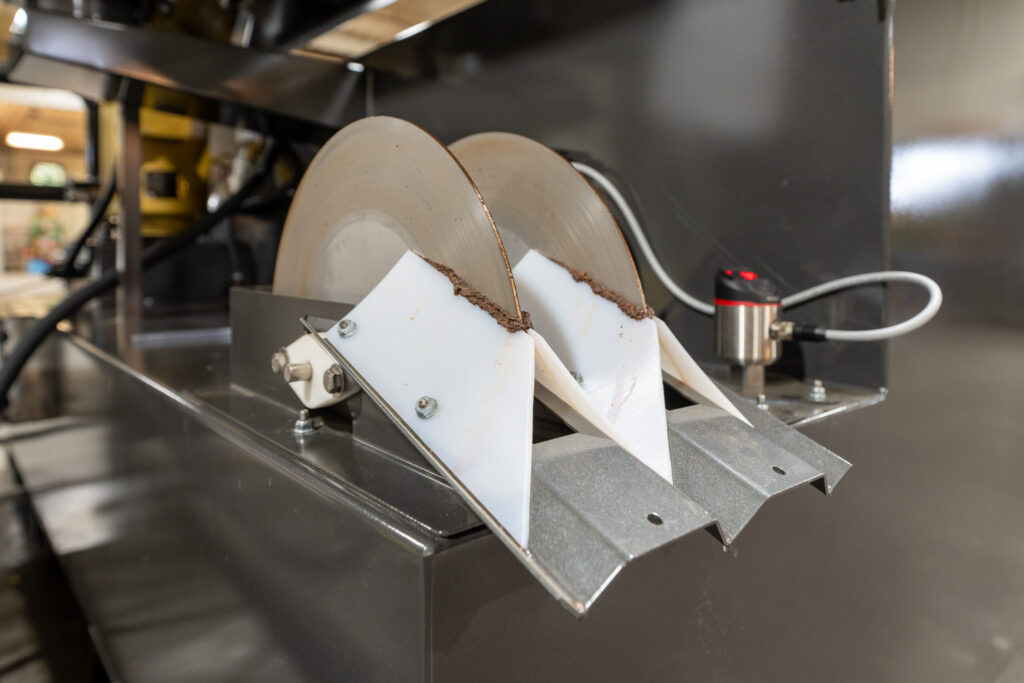

Parts Tumbling Basket

Tumbles parts for more dynamic cleaning.

The part tumbling basket provides a dynamic cleaning option by rotating the parts inside the basket. This constant movement ensures even distribution of detergent and water, effectively cleaning parts with complex geometries.

Water and Temperature Management Options

- Autofill System

- Keyence Level Sensor

- Foam Sensor

- Digital Temperature Readout

- Power Exhaust Vent

- Gas Heat

- Heater Upgrade

- Pump Upgrade

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Autofill System

Maintains proper water and detergent levels automatically.

The autofill system automatically refills the wash tank with the correct water-to-detergent ratio, ensuring optimal cleaning conditions are maintained throughout the wash cycle. This reduces the need for manual monitoring and improves overall efficiency.

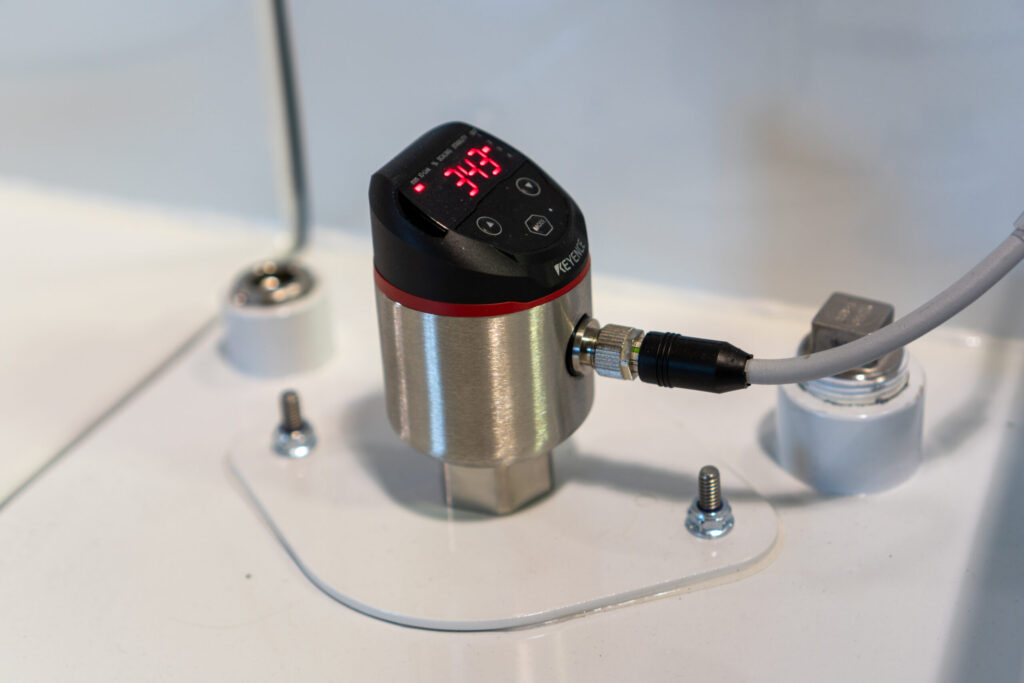

Keyence Level Sensor

Constant water level monitoring

This smart water level sensor lets you know exactly what your solution level is at all times. With PLC integration we can set multiple alarms and warnings for different solution levels. The additional flexibility this offers over a traditional float is crucial for washers that are in high production processes.

Foam Sensor

Monitors foam levels to prevent machine issues.

The foam sensor ensures that excess foam doesn’t overflow onto your floor. When foam is detected, the washer will shut down to mitigate the amount of mess in your facility. This helps maintain a safe and clean work environment for the operator.

Digital Temperature Readout

Accurate temperature control at your fingertips.

The digital temperature readout provides a precise reading of the wash water temperature. With the ability to adjust the temperature directly from the control panel, operators have better control over wash conditions, ensuring optimal cleaning.

Power Exhaust Vent

Evacuates steam for a safer and drier environment.

The power exhaust vent evacuates steam from the machine, preventing it from escaping into the workplace when the door is opened. This is especially important for drying applications, as it removes moisture-laden air, allowing for more effective drying inside the cabinet.

Gas Heat

Provides powerful heating while reducing electrical demand.

Gas heat is a great option for facilities where electrical capacity is limited, as it draws less electricity compared to electric heating elements. This option ensures the water reaches and maintains the required temperature without overloading the electrical system.

Heater Upgrade

Increased temperature control and maintenance.

For customers with critical temperature requirements, our heater upgrade option includes additional heating elements to ensure the water reaches and maintains the precise temperature needed. This upgrade is essential for applications requiring consistent high temperatures.

Pump Upgrade

Enhanced pressure for more effective cleaning.

Our pump upgrade option delivers higher PSI and GPM, offering greater water pressure and flow for a more effective cleaning process. Ideal for parts requiring intense washing, the pump upgrade ensures even the most stubborn contaminants are removed.

Waste Removal Options

- Dual Oil Skimmer

- Filtration Systems

- Filtration and Sump Sweep

- Drain Kit

- Oil Separation

- Discharge Pump

- Sludge Conveyor

Not sure exactly what you need, call 1-800-774-7900 or contact us.

Dual Oil Skimmer

Efficiently removes excess oil from the wash tank.

For applications with high levels of oil contamination, our dual oil skimmer effectively removes oil from the wash water, improving cleanliness and extending the life of the cleaning solution.

Filtration and Sump Sweep

Keeps the bath cleaner by agitating the debris.

The filtration and sump sweep system agitates the water to lift debris from the floor of the tank, making it easier for the filtration system to capture and remove contaminants. This feature extends the life of the wash water and ensures more effective cleaning.

Drain Kit

Provides convenient draining for stationary machines.

The drain kit includes a ball valve and collapsible hose for easy draining of the wash tank. This is particularly useful for machines that can’t be moved to a designated drain area, allowing for convenient and mess-free draining.

Oil Separation

Handles high volumes of oil contamination.

Our oil separation system is designed for applications with very high oil contamination. Unlike skimmers, this system can manage large volumes of oil, providing superior oil removal and maintaining the quality of the wash solution.

Additional Safety Options

- E-Stop

- Power Disconnects

- Door Interlock

- Lid Shocks with Auto-Lock

- Additional Employee Safety Labels

- Electrical Safety Options

- Increased Short Circuit Current Routing (SCCR)

- Wire Labels

- Light Curtain

- Absence of Voltage Test Point

Not sure exactly what you need, call 1-800-774-7900 or contact us.

E-Stop

Provides immediate emergency shutdown.

The emergency stop (E-Stop) button is a safety feature, allowing operators to instantly shut down the machine in case of an emergency. This ensures quick and effective response to any issue, improving overall workplace safety.

Power Disconnects

Provides a secure way to disconnect the machine.

Power disconnects allow operators to safely and securely cut power to the machine for maintenance or emergency situations. This feature enhances workplace safety by preventing accidental startups during servicing.

Door Interlock

Prevents the machine from operating while the door is open.

The door interlock system ensures that the machine will not operate unless the door is fully closed and then locks the machine while in cycle – protecting operators from potential hazards and ensuring safe operation at all times.

Lid Shocks with Auto-Lock

Automatically lock the door in the upright position.

This feature ensures safe and secure access to the wash area during loading and unloading, preventing accidental lid closure and reducing the risk of injury.

Additional Employee Safety Labels

Ensures compliance with safety protocols.

Additional safety labels are often required by large companies with strict safety protocols. These labels provide clear safety instructions and warnings, ensuring compliance with industry standards and improving workplace safety.

Electrical Safety Options

- Increased Short Circuit Current Routing (SCCR)

- Wire Labels

- Light Curtain

- Absence of Voltage Test Point

The Renegade Difference

Cleaning Excellence, Engineered for You

We are always willing to Engineer a solution - Just ask!

Not sure which features or options are right for your parts washer?

Not seeing exactly what you need?

Our experienced team is here to help guide you. Whether you’re configuring a new machine or upgrading an existing system, we’ll ensure you get the solution that’s tailored to your needs. Contact us!